Understanding the Role of a China CNC Precision Machining Supplier

In today's competitive manufacturing landscape, the demand for high-quality metal fabrication has never been more critical. Companies are continuously seeking reliable partners to fulfill their production needs. One such option that has emerged prominently is a China CNC precision machining supplier. But what exactly does this entail, and how can businesses leverage this to their advantage? In this article, we will explore the intricate world of CNC precision machining, delve into its benefits, and discuss why China stands out as a premier source for these services.

What is CNC Precision Machining?

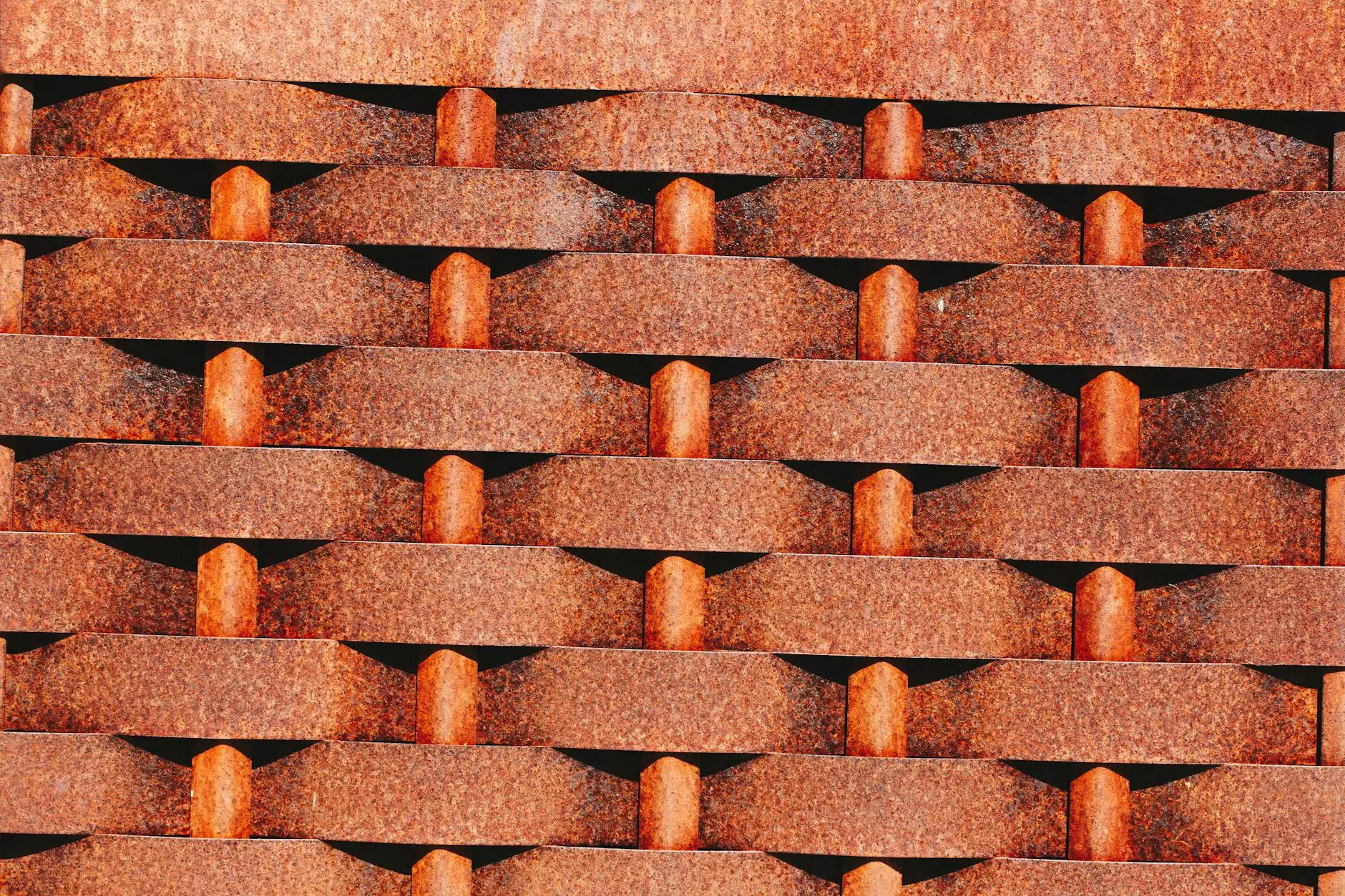

CNC, or Computer Numerical Control, machining is a manufacturing process that utilizes computerized controls to operate machine tools. This method allows for precise and intricate shaping of materials, including metals, plastics, and even wood. The process generally includes the following steps:

- Designing: Engineers create a detailed design using CAD (Computer-Aided Design) software.

- Programming: The design is then translated into a G-code using CAM (Computer-Aided Manufacturing) software.

- Machining: This code is fed into a CNC machine, which executes the machining operations.

- Quality Control: Post-production, rigorous quality checks are carried out to ensure precision and compliance with specifications.

The Importance of Precision in Machining

Precision is vital in machining operations. Whether producing complex components for the automotive industry or crafting intricate parts for medical devices, a deviation of even a fraction of a millimeter could lead to catastrophic failures. Therefore, partnering with a China CNC precision machining supplier can significantly enhance the quality and reliability of manufactured parts. These suppliers often employ advanced technology and skilled labor to maintain rigorous standards.

Why Choose a China CNC Precision Machining Supplier?

There are several compelling reasons to consider a China CNC precision machining supplier for your manufacturing needs:

1. Cost Efficiency

One of the most significant advantages of sourcing from China is cost savings. Chinese manufacturers typically benefit from lower labor costs, reduced overheads, and economies of scale. By outsourcing precision machining to a Chinese supplier, businesses can significantly reduce production costs without compromising on quality.

2. Advanced Technology

China is home to some of the most advanced CNC machining facilities in the world, equipped with cutting-edge technology. These suppliers invest in high-performance machinery that enhances the production process, ensuring higher efficiency and lower tolerances.

3. Skilled Workforce

China boasts a large pool of skilled labor trained in the latest manufacturing practices. This expertise enables them to handle sophisticated machining projects that demand both precision and creative engineering solutions.

Factors to Consider When Selecting a CNC Precision Machining Supplier

Choosing the right CNC precision machining supplier is crucial for the success of your project. Here are some vital factors to consider:

1. Quality Assurance Practices

Make sure the supplier has robust quality control processes in place. Certified facilities, adherence to international standards, and regular audits are indicators of a reliable supplier that prioritizes quality.

2. Communication and Support

Effective communication is essential when dealing with suppliers overseas. Choose a partner who offers clear communication channels and responsive customer support to address your queries promptly.

3. Flexibility and Scalability

An ideal supplier should be flexible enough to accommodate sudden changes in order quantities or design specifications. Additionally, they should have the capacity to scale production as your business grows.

Applications of CNC Precision Machining

CNC precision machining is employed in various industries, showcasing its versatility and essential role in modern manufacturing. Here are a few key areas:

- Aerospace: Components for aircraft engines and structural parts.

- Automotive: Engine parts, transmissions, and custom fittings.

- Medical Devices: Surgical instruments and implants.

- Electronics: Precision housings and components for devices.

The Future of CNC Precision Machining in China

The future of CNC precision machining in China looks promising. With continuous advancements in technology, such as the integration of AI and robotics, the capabilities of these manufacturing processes are expected to expand significantly. Innovators in the field are focusing on enhancing production speeds while reducing waste, making CNC machining an even more appealing option for businesses across the globe.

Conclusion

As businesses strive for excellence in manufacturing, partnering with a China CNC precision machining supplier emerges as a viable solution. With benefits ranging from cost efficiency to advanced technological capabilities, these suppliers can provide the support necessary for companies looking to enhance their operations. By considering factors such as quality assurance, communication, and scalability, businesses can make informed decisions to ensure the successful execution of their projects.

In an era where precision is non-negotiable, the importance of aligning with capable machining suppliers cannot be overstated. As the market continues to evolve, now is the time to explore the advantages that CNC precision machining from China can bring to your business.